What happens to my waste?

At Ellgia, we have a defined process for all our waste and recycling, from general waste to mixed recycling, food and glass.

Thankfully, gone are the days when waste was simply collected and the responsibility for its safe disposal belonged to someone else. We all have a legal and morally collective responsibility to ensure our waste and recycling materials are collected by an organisation that is competent, qualified, and registered to do so, that the materials are processed compliantly and efficiently, and that materials are recycled and recovered in facilities that are permitted to take them. We are all responsible for reducing the environmental impact of our activities and ensuring the highest levels of performance.

Segregation at Source

At Ellgia, we would always look to work with our customers to deliver the highest levels of waste and recycling segregation at the origin of its production. Starting 31st March 2025, UK businesses with more than 10 full-time employees will be required to separate recyclable materials such as glass bottles, paper, cardboard, metal (tins and cans), plastics, and food waste for recycling.

Ellgia provide a suite of collection services which cover dry mixed recycling (DMR) Cardboard, Paper & Card, Food, Glass and general waste. Recycling at source will not only improve the quantity and quality of the recycled material but in turn will reduce the environmental impacts of your activities and ultimately offer better value for money to you.

With the exception of dry mixed recyclate (DMR) single streams, recycling streams will be collected, consolidated at one of our permitted locations, processed to remove any minor contamination before being directed to final reprocessors for recycling.

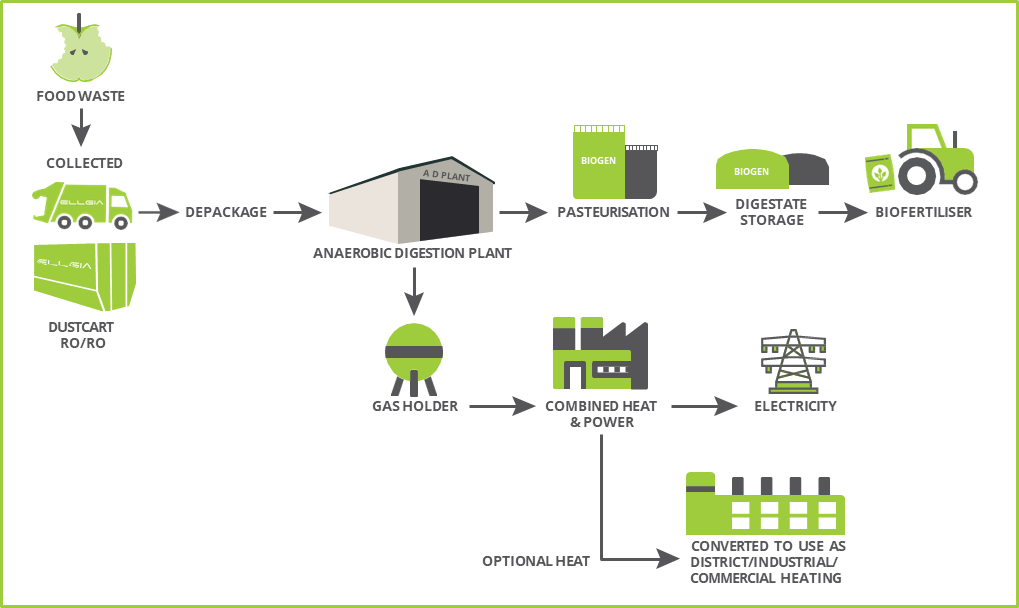

Food Waste

Food waste is generally processed through a technology called anaerobic digestion. Anaerobic digestion is recognised as one of the best methods for food waste recycling and dealing with farm waste and sewage sludge.

The word Anaerobic actually means ‘in the absence of oxygen’. The biogas naturally created in the sealed tanks is used as a fuel in a CHP (combined heat and power) unit to generate renewable energy, i.e., electricity and heat.

What’s left from the process is a nutrient-rich biofertilizer which is pasteurised to kill any pathogens and then stored in large, covered tanks ready to be applied twice a year on farmland in place of fossil fuel-derived fertilisers.

Glass

Glass can be melted down to make new glass products over and over again – it is 100% and endlessly recyclable. In fact, it’s the perfect circular economy material. And making new glass from recycled glass reduces CO2 emissions and energy use. Waste glass that has been processed ready for recycling is called cullet. Increasing use of cullet in glassmaking is a priority in the UK as every tonne of glass remelted saves 580 kg of carbon dioxide emissions.

Even when glass quality is too poor for remelting (that is, it contains too much of certain non-glass materials), it can still be used for a range of secondary applications, such as aggregate, an additive in building materials (including eco-cements and concrete), water filtration and blast cleaning.

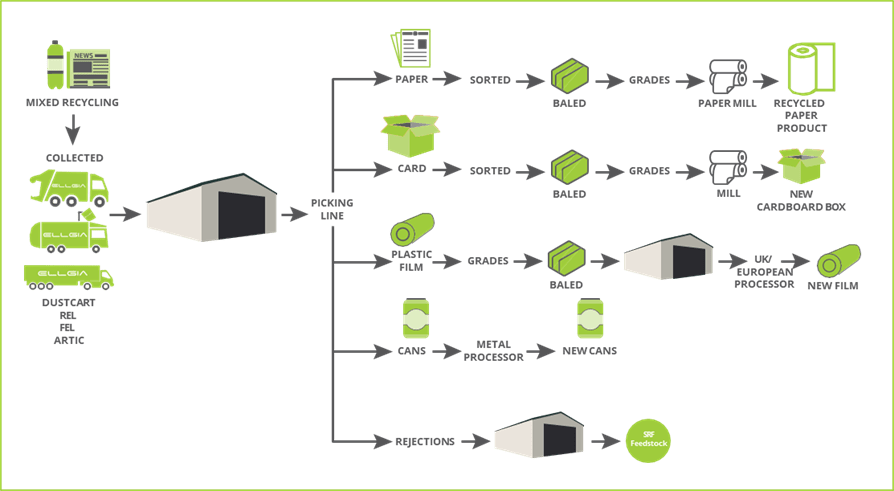

Dry Recycling

Mixed recycling streams require further processing to separate the materials into their constituent parts, the recycling mixed allowable is important to ensure that the best quality of separated materials is produced via the least amount of energy consumption from the separation processes.

Your DMR will first visit a Materials Recycling Facility (MRF) where the waste streams will be sorted into their components: Card, Paper, Coffee cups, plastics and metals. MRF’s processing operates a mechanised sorting process including:

· Screens & Trommels to remove large recyclable items

· Magnetic separation to identify ferrous metals

· Optical separation for plastics

· Air classification can help to separate light and heavy materials (paper for example)

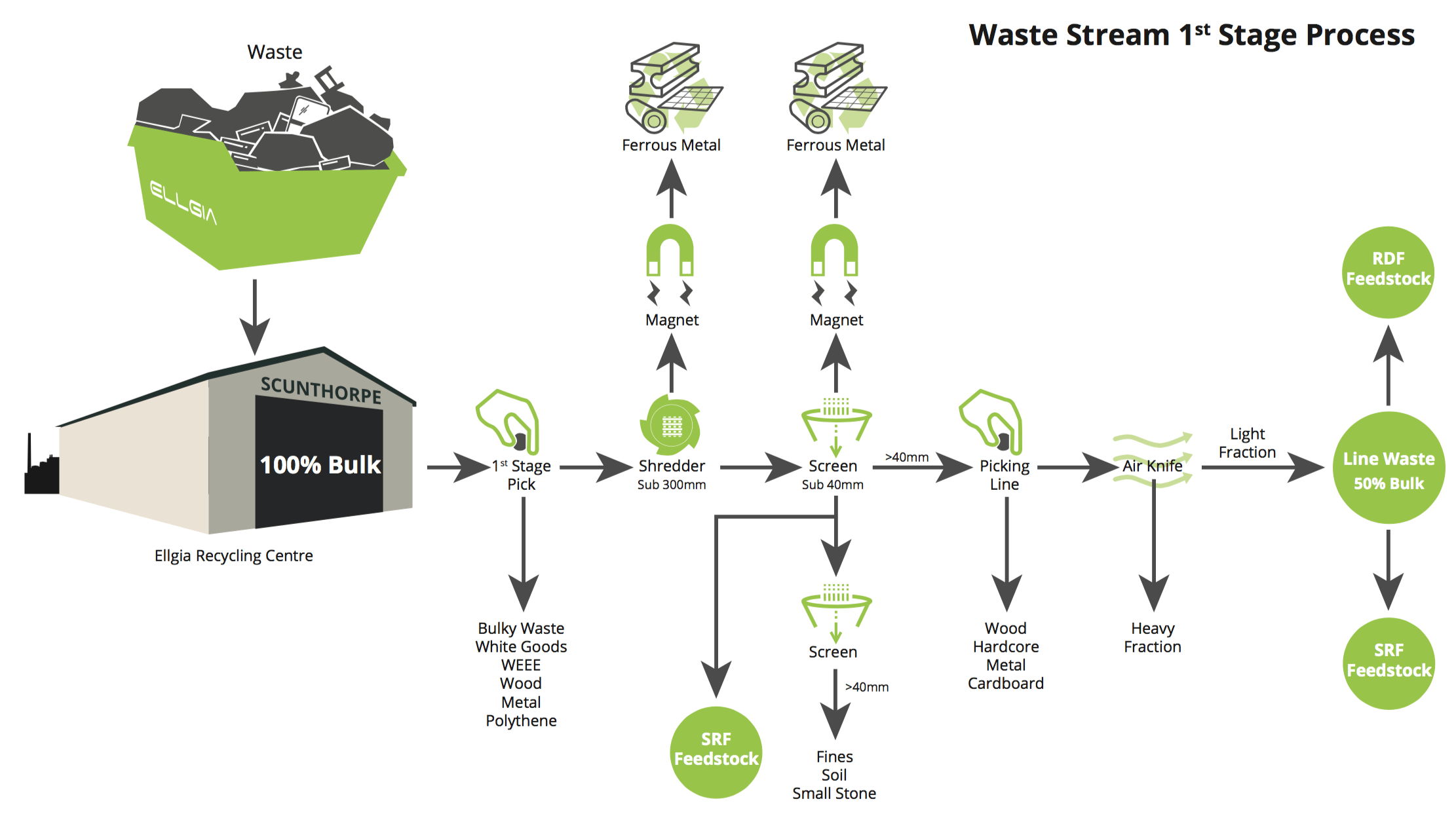

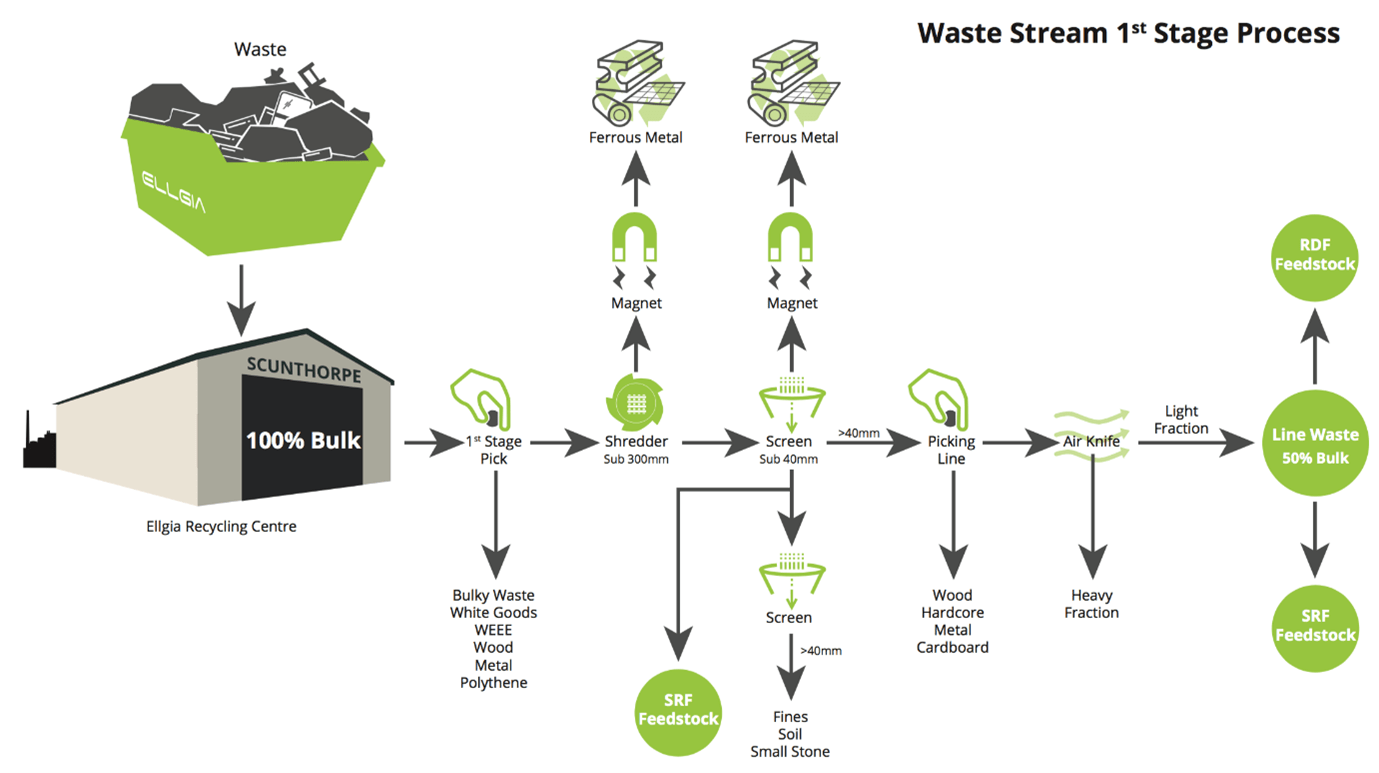

General Waste

Ellgia recognises it is not always possible for waste producers to optimise the separation of recycling materials from their waste streams for many reasons including resources, processes, downtime etc.

We will support our customers with helping to design a process that works for them and there is still an opportunity to improve recycling after the collection. Compactable waste collected is ultimately treated to become Refuse Derived Fuel (RDF) or Solid Recovered Fuel (SRF), however there are further opportunities in the fuel process to separate further recyclate and unsuitable materials.

Once the waste stream arrives on site, our first key decision is where we allocate the waste into our process. Through the waste description, intimate knowledge of our loading practices and high levels of waste identification training we can determine which of our processing lines are best suited to extract maximum value with the least amount of energy consumed and wastage.

The remaining materials are then processed into waste derived fuel, RDF or SRF.

You can watch our process here.

Our experience informs us that no two customers are the same and our approach to individually assessing the best solution for each site ensures the best outcome for the environment and the customer.

Want to find out more?

A dedicated member of our team is ready to help you.